CAST is a family affair with brothers Lars and Silas Chickering Ayers founding and growing the company with the headquarter located in the shadow of the Teton Mountains in Idaho.

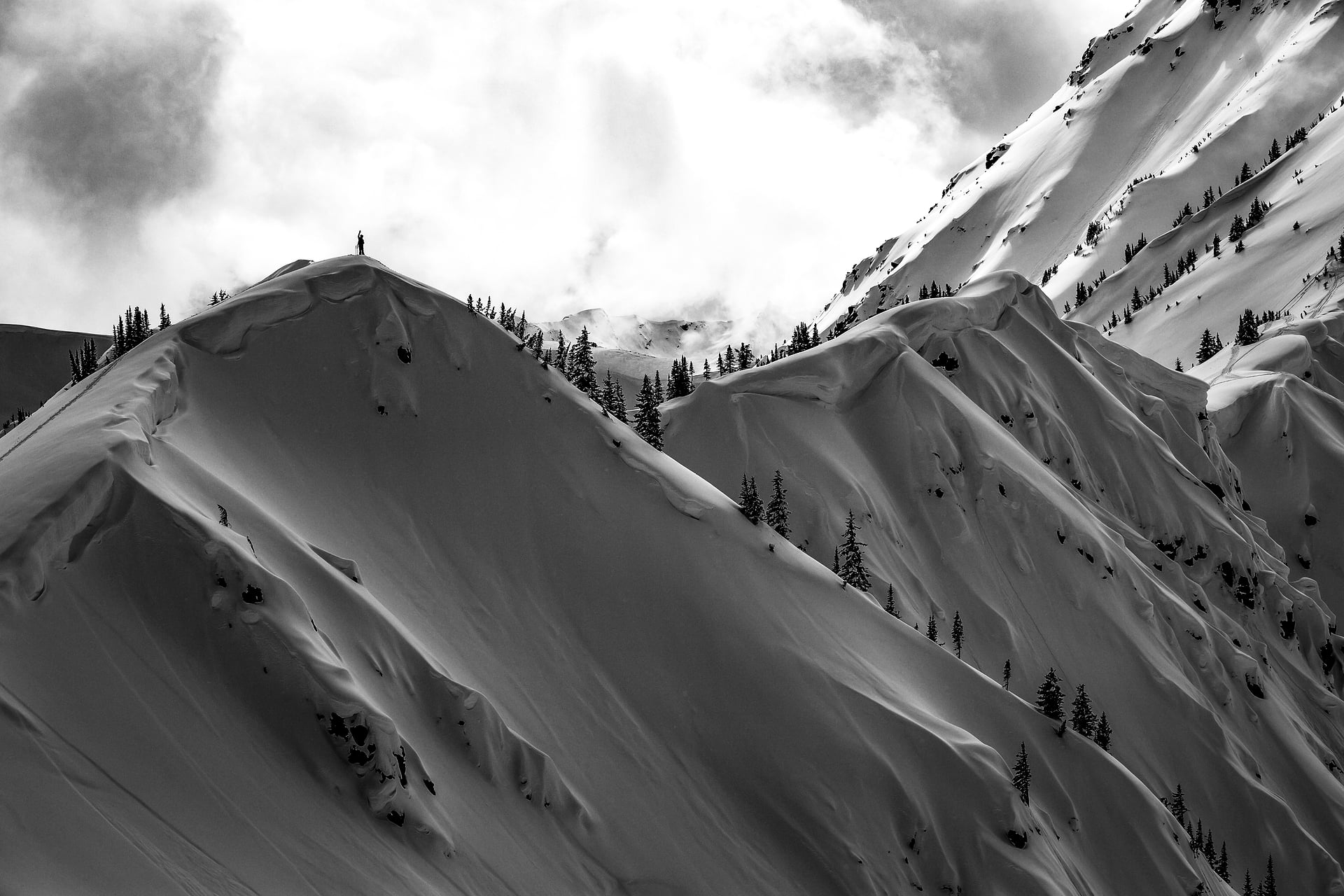

“It’s the journey, not the destination.” For many ski tourers, it’s about the latter: the descent. And if they’re going to earn their turns climbing a mountain, they want to be able to shred as aggressively as they wish on the way down — unhindered by their equipment.

Manufacturers of touring bindings were slow to meet that niche-market demand. Their solutions were compromises. Frame bindings performed well on the descent but were too heavy for effective ski touring. Concerns about pre-releasing from tech pin bindings also discouraged skiers who wanted to tackle high-consequence terrain aggressively.

A small group of skiers wanted the downhill performance of a high-end, full-metal high-DIN alpine binding, combined with the weight, functionality, and efficiency of a tech binding for touring.

saw the writing on the wall. They grew up in Montpelier, Vermont, but were raised at Mad River Glen, a small ski hill where their dad managed the ski patrol program (he recently retired). Their father, also a carpenter, passed along building skills to his sons that soon manifested in childhood bike bridges and jumps.

After graduation, Lars moved out west where he became a local at Alta, Utah, competed in the big-mountain contest circuit, won several domestic events, and eventually became a regular on the Freeride World Tour. His curiosity for engineering and product design also led to the development of an MFD-style binding prototype. He attended Vermont Technical College for a few semesters and gained essential design skills.

The younger brother, Silas, also achieved success in competitions. He and Lars shared the podium at the 2011 U.S. Extreme Freeskiing Championships, and in 2013, Silas won a Freeride World Tour event. After receiving an invitation to share a shop space from the telemark binding company 22 Designs in Driggs, Idaho, located in the heart of the Tetons, the brothers ultimately established their shop there.

CAST Touring began as a Kickstarter project, but the brothers' primary motivation was the death of their friend Ryan Hawks the year before. Hawks had become a third partner and was helping develop early prototypes. Tragically, Hawks sustained fatal injuries during a Freeskiing World Tour competition. “We named the company ‘CAST’ in honour of him,” says Silas. It’s a lesser-known word that describes a group of hawks.

Motivated by Ryan’s enthusiasm and the alarming experiences and glaring flaws of available touring bindings, which had led to injuries and fatalities in their sport, Lars and Silas began collaborating with a machinist in Salt Lake City. They produced 40 pairs of prototypes and started distributing them to friends and fellow athletes. The groundbreaking system allowed skiers to switch out the toe piece — replacing a tech-touring toe for climbing with an alpine binding for descending. The original design became the world’s first pin-tech touring system, offering the dependability and performance of a no-compromise alpine binding.

CAST has increased by more than 100 percent annually over the years. The company produced 300 pairs of its Freetour bindings in its first year, doubled that amount the following year, and now makes about 5,000 pairs annually.

“Just recently we’ve been able to ramp up production enough to keep pace with demand, allowing us to go from made-to-order to having inventory on hand, ready to ship.”

– Silas Chickering-Ayers

Currently, customers can purchase the CAST Freetour Pivot 15 or 18 binding or buy the Freetour Upgrade Kit to use on existing Look Pivot 15s or 18s. A bonus is that Freetours can be mounted using pre-existing drill holes.

The system is built on a set of screws onto which the toe pieces click. To begin skinning, skiers remove the Freetour alpine toe, then slide the 128-gram, auto-locking tech toe piece into place, and achieve the most efficient stride possible. The heel piece releases completely, so there’s no extra weight hanging on the boot like with frame bindings. When it’s time to ski, swap out the tech-toe piece for the alpine toe, which again locks into place automatically. Presto — a reliable, safe, and familiar binding system for the descent. Also now available is CAST’s Second Ski Kit, which allows skiers to use the Freetour system on multiple sets of skis for only $75 US, enabling skiers to travel with much less gear.

(now 38 and 33 years old), it's no surprise to learn that the full-capacity company handles everything in-house, from prototyping to computer numerical control (CNC) milling, materials testing, assembling, marketing, and more. At every stage, the brothers oversee quality control, ensuring CAST bindings are the most reliable touring bindings on the market. “We’re unique because our prototyping and R&D are much faster than at a big company,” says Silas.

Although Salomon, Marker, and others have introduced multiple bindings in what is known as the “hybrid” category, none have built the loyal following that CAST has. Freeride athletes worldwide trust CAST bindings for their safety.

Most recently, CAST moved into a new 10,000-square-foot factory that they built themselves. This guarantees future capacity growth and also accommodates the production of SNDR Products, a snowmobile rack and tunnel bag system for skiers and snowboarders.

“We launched SNDR together with our friend and skier Karl Fostvedt in the fall of 2024. We handle all production and fabrication in-house, and the sled skiing community has responded very positively,” says Silas.

and, for the most part, by word of mouth and people showing their friends.” This kind of third party endorsement is what ski companies crave — and it’s what’s fueled the steady rise of an innovative concept in just over a decade. From a garage-based beginning to a direct-to-consumer operation, to being offered by more than 70 dealers — including 50 international suppliers — Cast has been one of the most closely-watched developments in the fast-changing market of ski touring technology.

JAY DASH is an action sports and landscape photographer based out of Salt Lake City, Utah. In 2009, he left the corporate finance world in New York City and headed to the mountains. There he picked up a camera and taught himself how to shoot ski photos. Over time, Jay has learned the value of leaving the camera behind so he can enjoy such activities as split boarding, mountain biking, trail running, and scrambling for himself.

RELATED STORIES